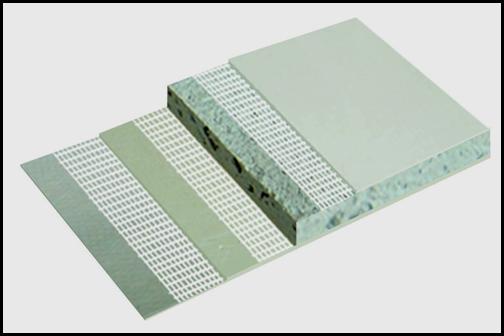

AN ALL NATURAL MAGNESIUM OXIDE COLD CERAMIC CEMENT BASED BUILDING SHEETING OPTION

REPLACES DRYWALL, OSB AND PLYWOOD SHEETINGS

AT COMPETITIVE DELIVERED PRICING TO PAPERLESS DRYWALL AND PLYWOOD PRODUCTS.

USED EXTENSIVELY IN ASIA FOR YEAR, AND RECENTLY USED AS BOTH INTERIOR AND EXTERIOR SHEETING ON THE LARGEST BUILDING IN THE WORLD, THESE PRODUCTS OUTPERFORM CONVENTIONAL MATERIALS IN MANY WAYS.

PLEASE CHECK OUT THE LINKS BELOW AND THEN FEEL FREE TO CONTACT MY OFFICE ANYTIME FOR MORE INFORMATION ON THESE FIRE, MOLD, WATER, AND SHRINK RESISTANT “BREATHABLE” OPTIONS FOR YOUR NEXT CONSTRUCTION PROJECT.

“AFFORDABLE “BREATHING WALL” BUILDING ENVELOPE DESIGN”,* A POWERPOINT PRESENTATION, EXPLORES A “BUILDING BIOLOGY” APPROACH TO HEALTHIER FRAME WALL ON CONCRETE SLAB CONSTRUCTION PRACTICES.

IT HAS BEEN MY LONG-STANDING PASSION TO BRING THE LEAST TOXIC, AFFORDABLE BUILDING OPTIONS TO GREEN BUILDING PROFESSIONALS AND HOMEOWNER IN THE USA.

MgO “CHINA-CRETE” FIBERBOARD IS NOW AVAILABLE IN THE USA!

I HAVE RECENTLY RETURNED FROM MY 8TH TRIP TO CHINA AND HAVE ESTABLISHED DISTRIBUTORSHIP (OEM) RELATIONSHIPS WITH FOUR OF THE TOP PRODUCERS OF MgO FIBERBOARDS IN CHINA.

MgO BOARD REPLACES DRYWALL, OSB AND PLYWOOD SHEETS

THE MAGNISIUM OXIDE CERAMIC CEMENT-BASED FIBERBOARD IS

FIRE, MOLD, WATER, & SHRINK RESISTANT & “BREATHABLE”. IT IS AN ALL NATURAL MINERAL SHEETING MATERIAL THAT HAS BEEN USED EXTENSIVELY IN ASIA FOR DECADES, AND RECENTLY WAS USED AS BOTH INTERIOR AND EXTERIOR SHEETING ON THE LARGEST BUILDING IN THE WORLD. * * * * * IT IS 100% ENVIRONMENTALLY FRIENDLY * * *

IT IS NOW AVAILABLE AT CONTAINER-LOAD DELIVERED PRICING COMPETITIVE TO PAPERLESS DRYWALL AND PLYWOOD PRODUCTS.

I’M THE CERTIFIED BUILDING-BIOLOGIST** AND AUTHORIZED OEM DISTRIBUTOR FOR SEVERAL MGO PRODUCTS IN THE USA–OFFERING HEALTHY BUILDING CONSULTING ALONG WITH COMPREHENSIVE APPLICATION AND FINISHING CONSULTING FOR OUR CLIENTS WORLDWIDE.

FOR ORDERS OR FREE ESTIMATES CONTACT:

SWANSON ASSOCIATES

6705 Hwy 290 West Suite 502-126 Austin Tx. 78735

Phone 512-288-9097 Cell 512-653-8624 Fax: 512-288-9096 Contact (gps@flash.net)

MgO-GENERAL (pdf file)

A few good research websites on Mgo:

www.ceralith.com (General overview of MgO uses)

www.bonesolutionsinc.com –MgO based bone replacement

www.lithistone.com (Artistic uses of MgO cement)

www.tececo.com (Australian MgO “Eco” cement)

www.geopolymer.org (General alternative cements info)

www.ecocreto.com (100% Pervious Portland/MgO cement)

www.chemicalceramics.com (Magnesium Oxy-Cloride-“Chinacrete”)

http://minerals.usgs.gov/minerals/pubs/commodity/magnesium/ (MgOcommodity info)

www.anl.gov (search under “Ceramicrete” )

www.bindancorp.com (MgO products licensed w /ArgoneLabs)

www.premierchemicals.com (search under “Library”section,then “Magnesia Cement”)

www.rosendalecement.net/html/chemistry.html natural cement from

Rosendale New York

Magnum BP MgO based building panelsSustainable Cement Report Pdf

Also, below is a summary of the project we are building in Austin with the MgO panels www.spiritu.us (our NewUrbanist/ Vastu city planning site)

CONCRETE RAINFOREST?

Submitted by: Tony Smith

There is a way to make our city streets as green as the Amazon rainforest. Almost every aspect of the built environment, from bridges to factories to tower blocks, and from roads to sea walls, could be turned into structures that soak up carbon dioxide, the main greenhouse gas behind global warming. All we need to do is change the way we make cement. John Harrison, a technologist from Hobart, Tasmania, reckons his alternative cement based on magnesium carbonate rather than calcium carbonate, could reduce climate change without sacrificing modern living. It’s a big claim, and Harrison has set about trying to convince the building industry to adopt his ideas. “The Kyoto Protocol was a good effort”, says Harrison ” but it got things wrong when it assumed that trees were the only things that could absorb carbon from the air.” Instead, he wants to replace the ubiquitous Portland cement with a substance that he calls ‘eco-cement’. “This magnesium based material,” he says. “could be cheaper to manufacture than Portland cement, more durable and soaks up CO2 as well,” and, cIaims Harrison, “if the building industry listens, cities and their suburbs could turn into sinks for C02, as effective as, for example, the naturaI grass and woodland they replaced”. Our modern world is largely built of Portland cement, invented almost 180 years ago by a Yorksbire stonemason called Joseph Aspdin. In 1824, he obtained a patent for “an improvement in the modes of producing artificial stone” that involved roasting chalk and clay in a kiln, grinding the resulting ‘clinker’ into a fine powder containing mainly calcium silicates and mixing it with water. This starts a complex chemical reaction that forms crystals of calcium silicate hydrate, for example, which hardens the mix. The 19th century was a time when the great cities of Britain were under construction, and many other inventors were working on artificial stone. But Aspdin cracked the problem by subjecting the ingredients to the ultra-high temperatures of a glassmaker’s kiln in his home town of Hunslet. He called the product Portland cement because of its resemblance to the most popular natural stone of the day, from the Isle of Portland in Dorset. Portland cement proved cheap to make and immensely versatile, and soon became the basic ingredient of both cement and mortar, the building blocks of every city on the planet. Every year, some 1.7 billion tonnes of Portland cement are now produced worldwide, a staggering quarter of a tonne for every 6 person on Earth. But there’s a problem. The manufacture of Portland cement produces massive amounts of CO2. This is partly because of the huge amounts of energy required to raise temperatures inside cement kilns to the 1450 0 C needed to roast the calcium carbonate (from chalk or limestone. And it’s also because the process of conversion itself creates CO2. For every tonne of Portland cement emerging from the kilns, roughly a tonne of CO2 gas escapes into the atmosphere. Cement manufacture is responsible for around 7 percent of total man-made CO2 emissions worldwide, a figure that rises above 10 percent in fast-developing countries such as China, which currently manufactures one in every three tonnes of cement made around the world. If we mean to control global warming this situation can’t go on. And, says Harrison, it need not. His solution, being brought onto the market by his small company ‘TecEco’ is to replace the calcium carbonate in the kilns with magnesium carbonate -a rock that occurs widely on its own, as the mineral magnesite, or in mixtures with calcium calbonate, such as dolomite. Magnesium based cements aren’t new. They were first developed in 1867, by French man Stanislas Sorel, who made cement from a combination of magnesium oxide and magnesium chloride. However, his mixtures couldn’t stand long exposure to water without losing their strength. Put a tower block of the cement in a Manchester or Seattle drizzle and it would eventually crumble away. Harrison’s magnesium carbonate based ‘eco-cements’, on the other hand, are chemically quite similar to calcium carbonate based Portland cement, are far more robust than Sorel’s material. And according to Harrison, his material has a number of major environmental advantages. For a start, the kilns don’t need to be run so hot. Magnesium carbonate converts readily to magnesium oxide at around 650 C. This means that emissions of CO2 from the energy used to fire kilns are roughly halved. The roasting process for the manufacture of eco-cements produces more CO2, but during setting and hardening, a process called carbonation reabsorbs most of this from the air. When conventional concrete made from Portland cement is fresh, water in the mix also slowly absorbs CO2 from the atmosphere. This solution then reacts with the alkaline calcium containing components in the concrete matrix to deposit calcium carbonate crystals, which reduce the strength of the concrete. But carbonation is quicker and more efficient in Harrison’s ecorement. Magnesium carbonate crystals are stronger than those of calcium carbonate, so they add to the material’s strength. If eco-cement is used to make porous materials like masonry blocks virtually all the material will eventually carbonate says Harrison. A tonne of concrete can end up absorbing up to 0.4 tonnes of CO2″ he says, “equalling about 100 kilograms of carbon. The opportunities to use carbonation processes to sequester carbon from the air are just huge”, says Harrison “It can take conventional cements centuries or even millennia to absorb as much as ecocements can absorb in just a few months”. This means that eco-cements quietly carbonating in a tower block could be performing much the same atmospheric function as a growing tree. And if eco-cements gained a foothold in our cities, they could immediately reduce the cement industry’s contribution to global warming, reabsorbing much of what was emitted in their creation. By directly replacing Portland cement with his eco- cement, Harrison estimates that we could eliminate over a billion tonnes of CO2 each year. The idea is “a world first”, says Fred Glasser of the University of Aberdeen’s chemistry department, one of the leading authorities on cement technologies. And eco-concrete has another way of proving its greenhousefriendly status. The material has huge potential for incorporating all sorts of waste matter, including carbon-based organic wastes that would otherwise rot or burn and release CO2 into the air. Adding inert waste such as fly ash to cement is routine in the industry. Butfor Portland cement there are strlct Iimits. Because the cement is alkaline, mixtures can react with aggregate to crack the concrete or make it brittle, sometimes causing failure. “Magnesium cements are much less alkaline, and the potential problems are far less,” says Glasser, who believes this could be one key to their eventual widespread use. “Organic waste from rice husts to sawdust, plastics and rubbers can all be incorporated as a bulking material in magnesium cement without it losing significant strength,” says Harrison, “thus turning the cement in buildings, bridges and so on, into significant stores of carbon. We have made bricks that are over 90% ash,” he says, “We can probably get three to four times more waste into our cement than Portland cement and would also massively reduce the amount of cement needed in the first place.” “His magnesium based cements may not meet every requirement,” he admits, “You might not want to replace Portland cement entirely for, say, bridge beams. But Harrison reckons magnesium cements could eventually replace 80% of cement. This move wouldn’t come cheap. Prime sources of magnesium carbonate, such as magnesite and dolomite, cost more to mine than calcium carbonate. But the price should fall with economies of scale, says Glasser. Harrison has already gone into manufacture. He sold his first ecocement bricks for a commercial building project in May this year. But he fears the cost of maintaining his patents could force him out of business before it really gets going. “The main problem,” says Glasser, “is that the building materials industry is intensely conservative, It prefers what it knows- Portland cement. Engineers are familiar with its mechanical properties. And of course, Portland cement is cheap. It may guzzle energy like there is no tomorrow, but a couple of dollars will buy you as much of the stuff as you can carry away from a hardware store. The market for Portland cement is so vast that it is difficult to see magnesium cements making much of an in road in the next 10 years.” says Glasser, “But perhaps, as the world tries to think up new ways of cutting back on its emissions of CO2, eco-cement may have its day. Our burning of fossil fuels is force-feeding Earth’s atmosphere with CO2 at a rate that vegetation can no longer absorb. The logical way out is to accelerate the formation of carbonate with our own man-made rocks. What better way” says Harrison, “than in cement? “.